Hot-dip galvanizing (HDG) offers several distinct advantages over other corrosion protection methods, such as painting, making it an ideal choice for a wide range of applications. Here are some of the benefits and details regarding the HDG process:

Low Maintenance Demands

Once galvanized, the steel requires minimal maintenance, reducing long-term costs and labor.

Extensive Life Cycle

The lifespan of galvanized steel can be significantly longer compared to painted steel, often lasting several decades.

Low Life Cycle Costs

Over the life of the structure, galvanizing is often more cost-effective than painting due to reduced maintenance and longer service life.

No Structural Down Time

Since the galvanizing process is completed before installation, there is no need for downtime to allow for curing or drying as with paint.

No Field Painting During Installation

Galvanized components are ready for use immediately upon delivery, eliminating the need for on-site painting.

- Structural Elements: Beams, bridge structures, cooling tower parts, pedestrian bridges, structural steel, transmission poles/towers, water/waste treatment structures.

- Infrastructure Components: Fence posts, highway guardrail/posts, overhead sign supports, signal light poles.

- Utility and Safety Items: Handrails, ladders, stair treads, platforms, pipe, plates.

- Transportation and Miscellaneous Uses: Boat trailers, garbage cans, grating, farm equipment.

Paint Coating:

Most organic coatings and paint films rely on their sealing ability and sometimes anti-corrosive pigments to protect steel from corrosion. However, they provide minimal or no protection to bare steel exposed by any damage, failure, or discontinuity in the coating. Once exposed, corrosion begins and rapidly spreads beneath the coating.

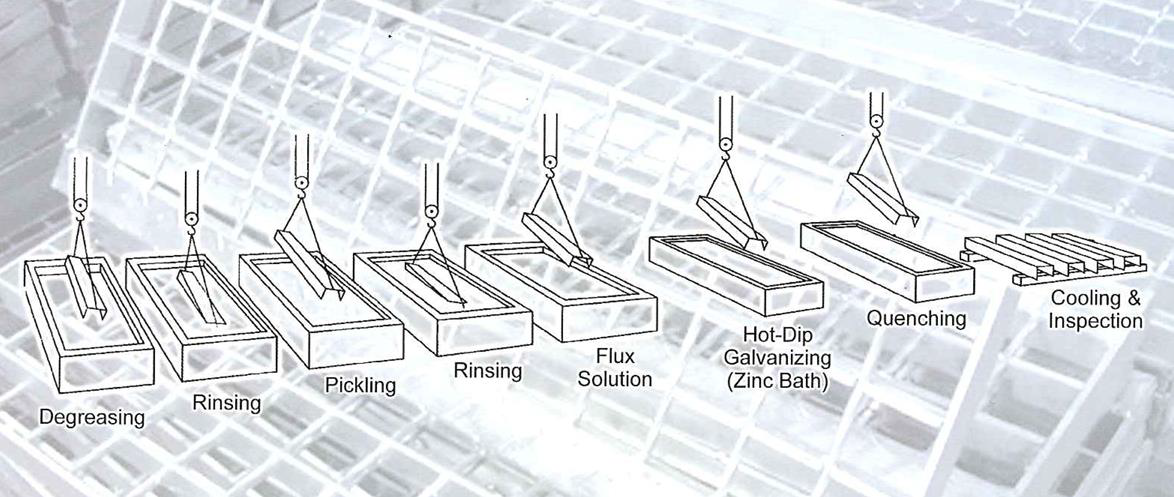

- Degreasing: Removal of oil, grease, dirt, and other contaminants using caustic soda at temperatures between 70°C – 80°C.

- Rinsing: Washing off caustic soda residues.

- Pickling: Steel is immersed in an acid bath to remove rust and mill scale, ensuring a clean metal surface.

- Rinsing: Removal of acid residues.

- Flux Solution: Immersion in a hot flux solution (zinc ammonium chloride) to prevent oxidation and ensure a chemically clean surface. Temperature: 60°C – 80°C.

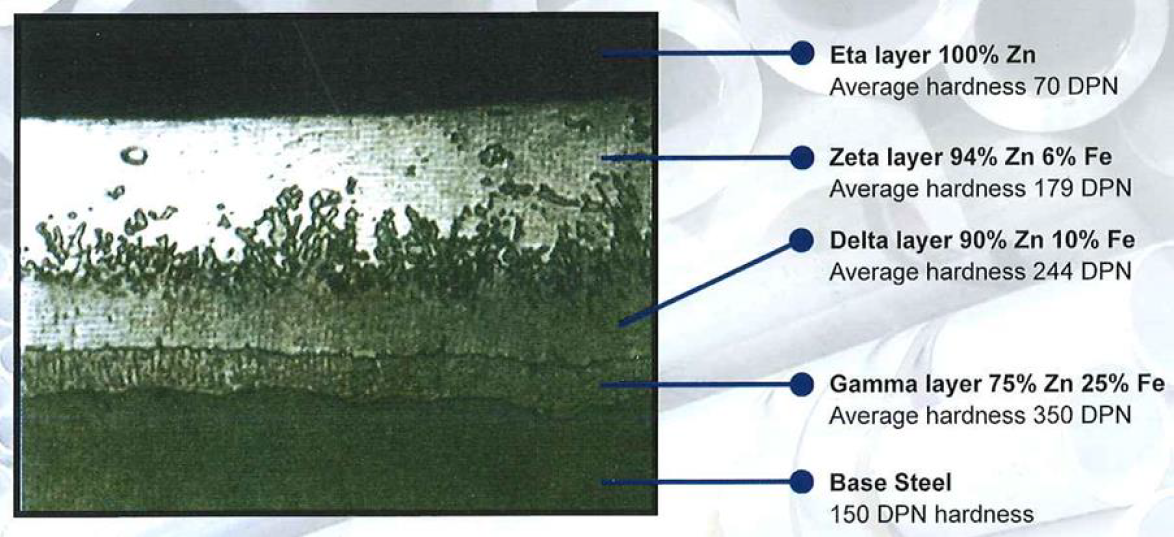

- Hot-Dip Galvanizing (Zinc Bath): Immersion in molten zinc (450°C – 455°C) where the zinc reacts with the steel to form zinc-iron alloy layers.

- Quenching: Controlled withdrawal and chilling in water to solidify the zinc coating, ensuring complete coverage.

- Cooling & Inspection: Transferring materials for final inspection, touch-ups, and removal of sharp edges.

- QC Inspection: Quality control checks to ensure coating integrity.

- Packing: Proper packing for transportation.

- Delivery: Transporting the galvanized items to the site or customer.

The zinc coating weight adheres to the minimum values specified in BS EN ISO 1461:2009.

| Category | Minimum Average Coating Weight for Any Individual Test Area | Equivalent Thickness (μm) | |

|---|---|---|---|

| Steel articles which are not centrifuged |

| 610 g/sq m (2.0 oz/sq ft) | 85 |

| 460 g/sq m (1.5 oz/sq ft) | 64 | ||

| 335 g/sq m (1.1 oz/sq ft) | 47 | ||

| Grey malleable iron casting | 610 g/sq m (2.0 oz/sq ft) | 85 | |

| Threaded work and others articles which are centrifuged | 305 g/sq m (1.0 oz/sq ft) | 43 | |